International Journal of Periodontics & Restorative Dentistry, 3/2015

DOI: 10.11607/prd.2378, PubMed ID (PMID): 25909520Pages 324-333, Language: EnglishMandelaris, George A. / Spagnoli, Daniel B. / Rosenfeld, Alan L. / McKee, James / Lu, MeiThis case report describes a tissue-engineered reconstruction with recombinant human bone morphogenetic protein 2/acellular collagen sponge (rhBMP-2/ ACS) + cancellous allograft and space maintenance via Medpor Contain mesh in the treatment of a patient requiring maxillary and mandibular horizontal ridge augmentation to enable implant placement. The patient underwent a previously unsuccessful corticocancellous bone graft at these sites. Multiple and contiguous sites in the maxilla and in the mandibular anterior, demonstrating advanced lateral ridge deficiencies, were managed using a tissue engineering approach as an alternative to autogenous bone harvesting. Four maxillary and three mandibular implants were placed 9 and 10 months, respectively, after tissue engineering reconstruction, and all were functioning successfully after 24 months of follow-up. Histomorphometric analysis of a bone core obtained at the time of the maxillary implant placement demonstrated a mean of 76.1% new vital bone formation, 22.2% marrow/cells, and 1.7% residual graft tissue. Tissue engineering for lateral ridge augmentation with combination therapy requires further research to determine predictability and limitations.

International Journal of Periodontics & Restorative Dentistry, 7/2014

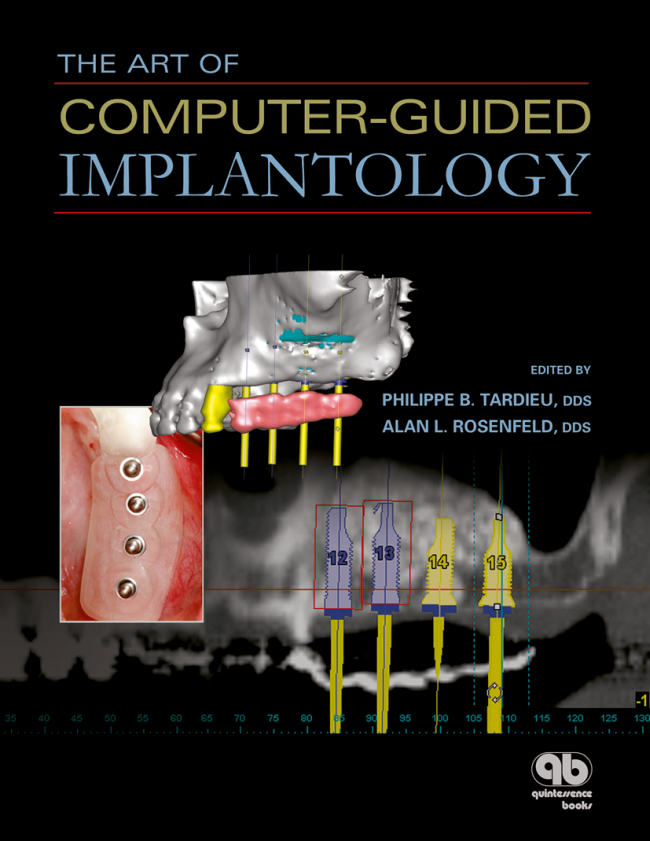

SupplementDOI: 10.11607/prd.2138, PubMed ID (PMID): 24956092Pages 58-69, Language: EnglishTestori, Tiziano / Robiony, Massimo / Parenti, Andrea / Luongo, Giuseppe / Rosenfeld, Alan L. / Ganz, Scott D. / Mandelaris, George A. / Del Fabbro, MassimoComputer-aided design/computer-assisted manufacture (CAD/CAM) guides for surgery are becoming a widespread tool in implant dentistry. This study sought to evaluate the accuracy and precision of a new guided surgery system. Twenty-five patients were treated in eight centers, and a total of 117 implants were placed using CAD/CAM surgical guides supported by bone, mucosa, and/or teeth. A postoperative computed tomographic (CT) scan of each patient was taken and superimposed on a preoperative CT scan to evaluate any discrepancies between the planned and actual implant positions (apex and platform positions), as well as the implant tilt. Implant placement using bone- and mucosa-supported guides was found to be more precise compared to using guides supported by teeth or a combination of teeth and mucosa. However, the differences were not statistically significant. The accuracy of the guided surgery system is in line with the data found in the literature. Considering the mean positioning discrepancies between the planned and actual implant outcomes, clinicians are advised to maintain a safe distance between implants and anatomical structures of at least 2 mm. In immediate loading cases, relining a provisional prosthesis to compensate for any discrepancies between the virtual and clinical implant positions is recommended.

International Journal of Periodontics & Restorative Dentistry, 3/2013

DOI: 10.11607/prd.1787, PubMed ID (PMID): 23593622Pages 289-296, Language: EnglishMandelaris, George A. / Vence, Brian S. / Rosenfeld, Alan L. / Forbes, David P.Pretreatment knowledge of crestal and radicular dentoalveolar zones and their associated thicknesses can improve risk assessment to meet esthetic and functional goals, particularly when discrepancies in anterior maxillary and mandibular arches exist and when an anterior protected articulation is to be achieved. This paper discusses a new classification of dentoalveolar bone phenotypes that differentiates the alveolar crestal zone from that of the radicular zone and classifies the thickness of facial bone at each compartment to aid in interdisciplinary dentofacial therapy risk assessment. The zone of crestal bone is defined as the region of the tooth alveolus measured from the cementoenamel junction (CEJ) to a point 4 mm apical. The dentoalveolar radicular zone is dependent upon the individual root length. It begins at a point 4 mm apical to the CEJ (base of the crestal zone) and extends the length of the tooth root. Dentoalveolar bone phenotype at both zones (crestal and remaining radicular alveolar aspect) can be categorized as either thick or thin. Thick is defined as >= 1 mm of facial bone width while thin is 1 mm.

International Journal of Periodontics & Restorative Dentistry, 3/2010

PubMed ID (PMID): 20386784Pages 275-281, Language: EnglishMandelaris, George A. / Rosenfeld, Alan L. / King, Samantha D. / Nevins, Marc L.The application of computed tomography (CT) and the use of computer software for dental implant therapy have significantly increased during the last several years. Dental implant positioning can be either "partially guided," where only osteotomy sites are prepared using sequential, removable surgical drilling guides (generated using computer software and through the process of stereolithography), or "totally guided," whereby one guide is used for osteotomy site preparation as well as implant delivery. Recently, the guided delivery of manufacturer-specific internalconnection implants has become available. Individualized protocols and specific instrumentation are employed under this approach to CT-based implant surgery. The purpose of this article is to expand on previous publications related to the use of prosthetically directed implant placement using computer software to ensure precise placement and predictable prosthetic outcomes. Three case reports are presented where precision-guided CT-based surgery was employed and the immediate delivery of a dental prosthesis was facilitated.

International Journal of Periodontics & Restorative Dentistry, 6/2008

PubMed ID (PMID): 19146052Pages 569-575, Language: EnglishMandelaris, George A. / Rosenfeld, Alan L.The antral sinus bone graft has become one of the most predictable and commonly used surgical procedures to augment bone in the posterior maxilla and thereby accommodate implant placement. Positioning the lateral wall during this technique has traditionally been an intuitive process, whereby the surgeon relies on mental navigation to achieve proper identification. The purpose of this article is to introduce a prototype cutting guide that is developed through the use of computerized tomographic imaging, computer software, and the stereolithographic process to precisely position the lateral wall and facilitate Schneiderian membrane elevation. This prototype cutting guide marks the beginning of applications for "guided bone grafting" and associated techniques that focus on enhanced precision and accuracy in bone regeneration surgery.

International Journal of Periodontics & Restorative Dentistry, 5/2006

PubMed ID (PMID): 17073359Pages 493-499, Language: EnglishRosenfeld, Alan L. / Mandelaris, George A. / Tardieu, Philippe B.Part 3: Stereolithographic Drilling Guides That Do Not Require Bone Exposure and the Immediate Delivery of TeethPrevious publications have reviewed the concepts of implant diagnostics and computerized tomographic imaging used together to create an atmosphere of collaborative accountability. The use of SimPlant software in combination with stereolithographic medical modeling facilitates the fabrication of surgical drilling guides, which assist in precise placement of dental implants. In this article, the use of gradient density scanning appliances will be discussed. This type of scanning appliance allows tooth- or mucosa-supported surgical drilling guides to be fabricated and used for implant placement without bone exposure. The use of the SAFE System will be introduced, along with its application in simplifying the immediate-loading prosthesis concept, which can often bypass the need for traditional dental impressions.

International Journal of Periodontics & Restorative Dentistry, 4/2006

PubMed ID (PMID): 16939016Pages 347-353, Language: EnglishRosenfeld, Alan L. / Mandelaris, George A. / Tardieu, Philippe B.The purpose of this paper is to expand on part 1 of this series (published in the previous issue) regarding the emerging future of computer-guided implant dentistry. This article will introduce the concept of rapid-prototype medical modeling as well as describe the utilization and fabrication of computer-generated surgical drilling guides used during implant surgery. The placement of dental implants has traditionally been an intuitive process, whereby the surgeon relies on mental navigation to achieve optimal implant positioning. Through rapid-prototype medical modeling and the ste-reolithographic process, surgical drilling guides (eg, SurgiGuide) can be created. These guides are generated from a surgical implant plan created with a computer software system that incorporates all relevant prosthetic information from which the surgical plan is developed. The utilization of computer-generated planning and stereolithographically generated surgical drilling guides embraces the concept of collaborative accountability and supersedes traditional mental navigation on all levels of implant therapy.

International Journal of Periodontics & Restorative Dentistry, 3/2006

PubMed ID (PMID): 16836163Pages 214-221, Language: EnglishRosenfeld, Alan L./Mandelaris, George A./Tardieu, Philippe B.The need for an accurate diagnosis and treatment plan remains essential for predictable treatment outcomes with dental implants. Advances in computerized tomography (CT) technology now enable the execution of a surgical outcome based on presurgical planning. Precise implant placement no longer relies on socalled mental navigation but rather can be computer guided, based on a threedimensional, prosthetically directed plan. Current CT technology enables all implant team members to embrace the concept of collaborative accountability, which can ensure consistent outcomes. Clinicians can fabricate an implantsupported prosthesis presurgically using patients' CT scan data. The purpose of this paper is to discuss the use of scanning appliances to transfer clinically relevant prosthetic outcome information to a CT data set. With SimPlant software, this information can be used to provide a pretreatment outcome analysis, which can be used for fabrication of stereolithographic models and surgical drilling guides used during osteotomy preparation.